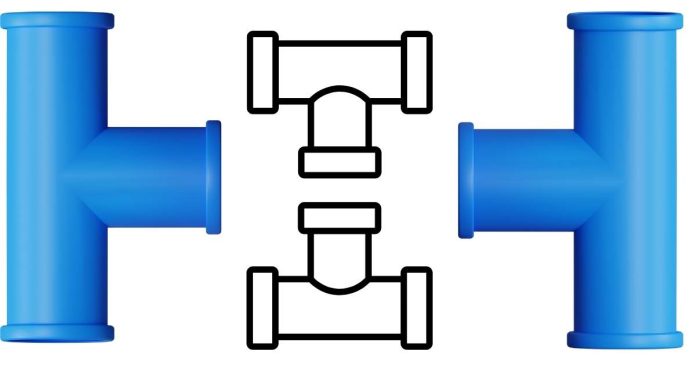

A tee joint is a type of weld where two metal pieces are joined at a 90-degree angle, forming a “T” shape. Here’s how you can create a proper tee joint step by step:

- Prepare the Metal Pieces: Start by cleaning the surfaces to remove dirt, rust, or grease. Use a grinder or sandpaper to ensure smooth, weldable edges.

- Set Up the Joint: Position one metal piece upright (perpendicular) against the horizontal piece to form the “T” shape. Use clamps or a magnetic holder to keep the pieces in place.

- Tack Weld: Apply small welds at the edges of the joint to hold the pieces together. This ensures alignment and prevents movement during welding.

- Adjust Welding Settings: Set your welder to the appropriate settings based on the metal type and thickness. For example, use a lower amperage for thin metals and a higher one for thicker materials.

- Begin Welding: Start from one end and move along the seam, using a continuous or stitch weld technique. Maintain consistent speed and angle for even penetration.

- Cool and Inspect: Allow the joint to cool, then inspect the weld for uniformity and strength. Remove slag (if using a stick welder) and smooth the weld with a grinder, if needed.

Proper preparation and technique are key to a strong and clean tee joint.