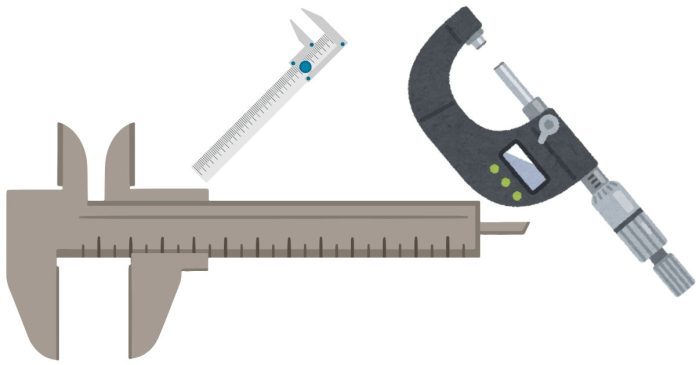

A micrometer caliper is a precision measuring instrument used to measure the dimensions of small objects with high accuracy. It is commonly used in mechanical engineering, machining, and quality control to measure the thickness, diameter, or depth of objects with precision down to fractions of a millimeter.

The least count of a measuring instrument refers to the smallest length that can be measured accurately by that instrument. In the case of a micrometer, the least count defines the smallest unit of measurement that can be reliably read from the device.

Understanding the Components of a Micrometer

A typical micrometer consists of the following key components:

- Anvil: A stationary surface against which the object is placed for measurement.

- Spindle: A movable part that is turned to bring the object closer to the anvil, which measures the object’s dimension.

- Thimble: The rotating part of the micrometer that is turned to move the spindle.

- Scale: The scale on the sleeve and thimble allows the user to read the measurement.

Calculation of Least Count of a Micrometer

The least count of a micrometer can be calculated using the following formula:

Least Count=Value of one main scale reading−Value of one circular scale reading\text{Least Count} = \text{Value of one main scale reading} – \text{Value of one circular scale reading}

For a standard micrometer:

- The main scale typically has divisions representing 1 millimeter (mm).

- The thimble scale usually has 50 divisions (in a metric micrometer).

If each division on the thimble represents 0.02 mm, the least count is calculated as:

Least Count=1 mm50=0.02 mm\text{Least Count} = \frac{1 \text{ mm}}{50} = 0.02 \text{ mm}

So, the least count of a metric micrometer (which measures in millimeters) is typically 0.01 mm (if it has 100 divisions on the thimble) or 0.02 mm (if it has 50 divisions).

The least count of a micrometer caliper in millimeters is usually 0.01 mm or 0.02 mm, depending on the number of divisions on the thimble scale. This precision makes the micrometer an essential tool in industries that require exact measurements of small objects, such as manufacturing, engineering, and scientific research.